Imagine Natural Solid Hardwood Flooring Instead Of Your Old Tiles In Just One Day*

Solid Wood With Clip Installation Is:

✔ Made of one piece of natural wood

✔ Without chemicals and no glue

✔ Easy to sand and restore

✔ Free from formaldehyde evaporation

✔ A pure indoor climate

✔ Made in Denmark with Worldwide certification

The key to a clean indoor climate and sustainability

↓Meet the Clip↓

Easy Steps To Get Your Natural Wood Flooring

How does clip installation works?

The clip system works by securing the planks together while allowing for natural expansion and contraction due to changes in temperature and humidity. The clips are inserted into pre-milled grooves on the underside of the planks, holding them in place without fixing them to the subfloor.

This method prevents deformation by ensuring that each plank can move independently while remaining securely interlocked with the others. The system distributes tension evenly across the floor, preventing warping, cupping, or big gaps, and maintaining long-term stability and durability.

Astonishing hardwood flooring as a result

Quick benefit highlights

100% Solid wood

Nature warm material

Quick & Easy Installation

No additional treatment

Great for renovation

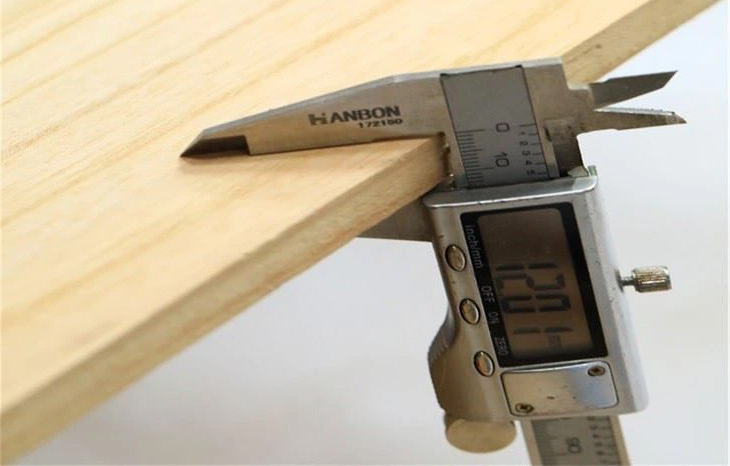

Small construction height

The essence of sustainability

Pure indoor air

Heritage of pure Danish design tested by time

As a young Danish graduate in forestry, Flemming Juncker had the foresight to recognize the poor economic state of the Danish forests. In order to address this issue, he saw the need to discover new uses for the wood that had previously only been utilized as firewood or left to remain in the forests.

In 1930, Juncker established a sawmill with the intention of producing 40,000 railway sleepers from beechwood for DSB (The Danish State Railways). To accomplish this, he leased 7,000 m² of land from Køge Shipyard in Denmark and purchased a frame saw from Sweden. While the production of railway sleepers was intended to be a one-time project, Juncker sold the remaining wood to Køge Timber Factory and was then tasked with finding alternative methods for disposing of the excess wood.

It was during this time that Juncker conceived the idea of creating 2-strip beech parquet boards, which involved assembling two rows of staves into one board using a “Lindermann machine”. The aim of this invention was to replace the popular Swedish pinewood floors in the Danish housing market, which proved to be successful. This innovation laid the foundation for Junckers’ solid hardwood flooring business.

*Clip installation method maximum capacity 50 sqm/day by one team of two installers. Doesn’t count delivery time and site preparation.